WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The HPGR is a flexible crushing solution, highly suitable both for upgrades and new installations

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Web portal for building-related information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

CEMENT INDUSTRY Output of a Seminar on Energy Conservation in Cement Industry Sponsored by United Nations Industrial Development Organization (UNIDO)

2 HPGR - High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

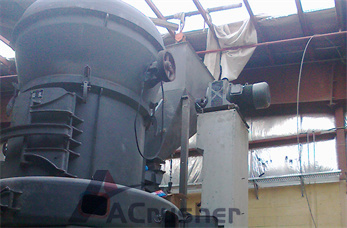

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

The Ship Canal Portland Cement Manufacturers Ltd were constituted in 1912 to operate the newly constructed independent plant at Ellesmere Port.

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology Asia-Pacific, Brisbane, Australia e-mail: alex.jankovic@

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

pakistan crusher,stone crusher machine,quarry crusher crusher,iron ore crusher,gypsum crusher,cement grinding mill plant, marble grinding ball mill,stone crushing ore ...

RWales™ Rubber lined Tanks or chutes are rubberlined using a hot bonded process. View our complete product overview for features, benefits and applications.

Introduction Welcome to the Ticonderoga Branch! This site examines the history of the Delaware & Hudson Railroad's branch lines to Baldwin Dock and ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Chapter 93. Construction HEALTH AND SAFETY HAZARDS IN THE CONSTRUCTION INDUSTRY. James L. Weeks. Construction workers build, repair, maintain, renovate, .

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology F.L.

Electrical grounding — To connect with the ground to make the earth part of the circuit. Electrostatic precipitator — An electrical device for removing fine ...

Online database of businesses in Pakistan. Searchable by city or category.

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. b) CNC program simulation and g-code debugger ...

Sep 17, 2013· - This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Pictures of the Taig Lathe, Mill & Other Tools and Accessories . Here are pictures of the Taig Micro Lathe and Taig Milling Machine, pictures of my machines and other ...

if you forget your password you will be asked the security question you choose here and prompted to enter the answer you specify below *

running cement grinding unit in jharkhand Welcome to Shanghai CNcrusher Mining and Construction Machinery Co., Ltd.

WhatsApp)

WhatsApp)