WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Iron ore fines of −10 mm size and limestone are ground together in a ball mill to ... Influence of raw ... Influence of raw material particle size on quality ...

CEMENT GRINDING OPTIMISATION ... and area of raw material preparation is not ... The basis for modeling the two-compartment ball mill is the perfect mixing ball ...

Ball Mill From China Zenith. This page is about the zenith Ball Mill for silicate, cement, ceramic,chemical fertilizer.

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal ...

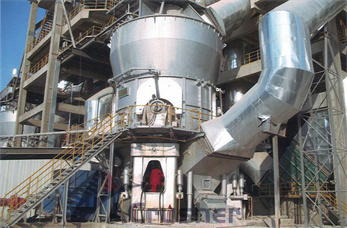

Grinding Mill Ball Mill Raymond Mill Vertical Mill High Pressure Mill MXB Coarse Powder Mill MTM Medium Speed Mill ... Home > Mill > raw mill pada pabrik semen ...

dry ceramic ball mill,US $ 20,000 - 72,000 / Set, New, Ball Mill, AC Motor.Source from Zhengzhou Jiangtai Heavy Industrial Machinery Co., Ltd. on Alibaba.

increase raw ball mill. The analysis of the influence of ball sizes in SAG grinding hasn't evaluation from effect on process parameters inside the mill, grinding ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed - Critical Speed needs.

adjusted classifiers for the raw meal and cement ... Getting more from the cement ball mill with ... installing a high efficiency classifier is to increase the mill

OPTIMIZATION OF PLANT OPERATIONS & TROUBLE SHOOTING ... K#4 ball mill up gradation with installation of KHD RPS-10 Roll Press for limestone ... increase in Raw .

Grinding trends in the cement industry ... 9 Ball mill from Sinoma for ... is a practical method in cases where the raw materials for clinker manufacturing are ...

A non-linear regression technique was applied to process the raw ... Given the ball distribution ... of solid materials by a ball mill–effect of ball ...

in order to increase the flow of materials to be polished, and so to increase production capacity. ... The ball mill in the production of dry method, the fluidity is reduced ...

Highlights Circulating load and classification efficiency effect on ball mill capacity revisited. Relative capacity model introduced and validated ...

ball mill can be divided into Ceramic Ball Mill, cement ball mill, coal mill and raw mill. ... To increase efficiency of the mill one would have to tune the rotation velocity so ...

High-efficiency mill grinding all types of raw materials. ... The most effective separator for new and old coal grinding ball ... Upgrade your gear unit to increase ...

Cement Plant,Ball Mill ... A few of divided crude powders pass the feed-in and then back to the crudely milling part a second time to increase ... cement ball mill ...

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power ...

Quick and Easy Black Powder Ball Mill - Skylighter. How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

CEMENT INTERNATIONAL 4 2/2013 4 VOL. 11 65 1 Introduction There is no question that vertical roller mills like the Loesche Mill offer significant advantages over ball ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Mill Charge Load Calculation. ... drying capacities for raw mills, ball ... Variable competency ore 4 High ball charge SAG mill (15 to . Increase the mill load by ...

This page is provide professional how to increase ball mill grinding rate information for you, we have livechat to answer you how to increase ball mill grinding rate .

WhatsApp)

WhatsApp)