WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Horizontal Cement Clinker Grinder. Cement Raw Material Crushing And Grinding | Manganese Crusher. ... Cement mill,clinker grinding plant,raw mill for Cement .

ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 3, Issue 5, November 2013

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

In recent years extensive refocusing has taken place and the company is today a highly specialised and world leading supplier of equipment and consultancy to the ...

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

raw grinding mill for cement . ... The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, ...

The mission of the State Board of Equalization is to serve the public through fair, effective, and efficient tax administration

Global Cement online portal for all things cement related

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Location: Grid reference: SP93431525; x=493430; y=215250; 51°49'41"N; 0°38'39"W; Civil Parish: Pitstone, Buckinghamshire; Clinker manufacture operational: 1937-1991

Cement Manufacturing Technologies. ... A raw mill is the equipment used to grind raw materials into ... and other methods are the same as the material or clinker mill.

The below excerpts are from various talks and articles by and on Bill Wilson, and were compiled by Jim Burwell. They reveal a wealth of the thinking and insight of ...

Cement manufacturing - raw materials. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless ...

Raw materials ... Cement manufacturing - brief description of a cement mill. Cement clinker is usually ... with different size grinding media. As the clinker ...

Grinding occurs at the beginning and the end of the cement making process. Approximately 1.5 tonnes of raw materials are required to produce 1 tonne of finished

Concrete is a hardened building material created by combining a chemically inert mineral aggregate (usually sand, gravel, or crushed stone), a binder (natural ...

Commercial Food and Cheese Chopping and Cutting Equipment. Schier Company Inc. has a wide variety of cutters available including grinders, shredders, flakers and ...

Cement microscopy. Cement microscopy is a very valuable technique, used for examining clinker, cement, raw materials, raw feed and coal. Every stage of the cement ...

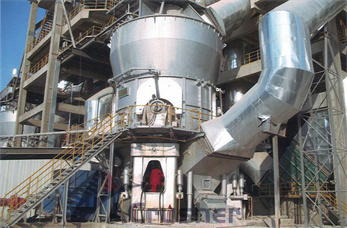

Cement Clinker Grinding Mill Raw Mill In Cement Plant Cement Vertical Mill, Find Complete Details about Cement Clinker Grinding Mill Raw Mill In Cement Plant .

The process of pelletization enables converting Iron Ore Fines into "Uniformed Sized Iron Ore Pellets" that can be charged into the blast furnaces or for ...

Cement production line Mainly by crushing and pre homogenization, preparation of raw meal homogenization, preheating and decomposing, cement clinker sintering, cement ...

The raw material preparation stage of cement ... And despite the extra grinding, raw material fineness ... The nearly universal use of roller mills for raw ...

Crusher Machine For Sale. ... The cement mill grinds the clinker to a fine ... Process Overview Mining & Crushing Raw Mill Grinding Raw Meal Homogenization Pyro ...

SBB's steel glossary is great for finding the definition for any steel term associated to the industry.

WhatsApp)

WhatsApp)