WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Chapter 11 Briquetting of charcoal. Most of this undesired high ash material can be separated by screening the fines Tar and pitch from coal Ability to produce fine ...

Factors to be monitored are size distribution of coal and magnetite, plus screening ... The M/C ratio is already rather low for a DMC for fines system and in ...

It is standard practice in coal processing plants to de-slime the feed to fine coal ... feed and much of these ultra-fines report to the spiral product.

Fine Coal Recovery from Tailings Impoundment's. Process Requirements. The original process for the Wollondilly plant was designed for the recovery of

Coal Product Upgrade Using New Screening Technology lrshad Omar 0plimum Colliery Introduction Developments in spiral concentration technology and test work carried out by

For the revising of MT 58—93 "Methods for screening test of coal fines",this paper put forward some suggestions such as adding 0.030 mm aperture,stressing necessity ...

Fines Generation at Morupule Coal Mine (MCM): Based on ROM Coal . Refilwe S. Tshipa¹, Antonie F. Mulaba-Bafubiandi¹, Nkhumeleni Tshiongo¹

literature of the British coal industry references were made to the screening of coal as early as 15C9, ... This mining procedure left the fines in the

Coal Supply Hopper COAL PREPARATION STAGES DOUGH PREPARATION STAGES BRIQUETTING STAGE CURING STAGE Screening Limiting Particles Sizes Rotating .

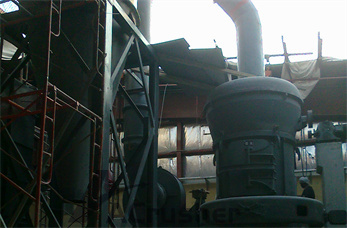

Low Fines Coal Crushing Machinery 69 Views. ... coal fines processing to pellets, ... Coal screening machine suppliers,for sale,plant,price,exporter ...

Run-of-mine (ROM) coal. The coal delivered from the mine that reports to the coal preparation plant is called run-of-mine, or ROM, coal. This is the raw material for ...

The processing of coal and ores often requires the flotation and washing procedure. Virto Group's multifrequency ScreenX line is a specialist line of screening ...

Flip Flow technology is cutting edge design which enables awkward materials to be screened and turned into a profitable and useable commodity as opposed to a costly ...

Discussed are the main features, application status, problems confronted and possible solution measures of screening machines for wetted coal fines both domestic and ...

This study was subsequently initiated by Technology R&D to establish the mechanism of fine coal generation during wet screening, ... Screening; Coal fines; Coal;

Iron Ore Fines Presentation 2009 screening of iron ore. • They are used ... If documentation states cargo is iron ore fines the Master ... causes the fine material ...

The efficiency of fines (-28 mesh) removal over a range of screen openings and surface moistures was determined for a western Kentucky coal. Three test series were ...

Fine coal screening performance enhancement using the ... which treats typically −1 mm size coal fines needs ... K. Reyneke Fine coal screening using the ...

WASTE COAL RECLAMATION by Joseph W. Leonard William F. Lawrence and One of the major problems facing the electric power generating industry is

company has been engaged by TransAlta Centralia Mining to collect, transport, process and dispose of waste coal slurry created during the operation of the

SCREENING COAL FINES BEFORE CRUSHING IN PREPARATION FOR COKING. on ResearchGate, the professional network for scientists.

CLEANING AND DEWATERING FINE COAL USING HYDROPHOBIC DISPLACEMENT Kara E. Smith ABSTRACT A new processing technique, known as hydrophobic .

Toggle navigation. Home; About SciTech; FAQ; Connect your ORCID iD; Save searches, create alerts, and export data: ... Searching: Full Text

Coal, Peat and Oil Shale ... It is the residue from screening coke. The ... (BC), SIEC code 0320: A composition fuel made by moulding hard coal fines into briquette ...

WhatsApp)

WhatsApp)